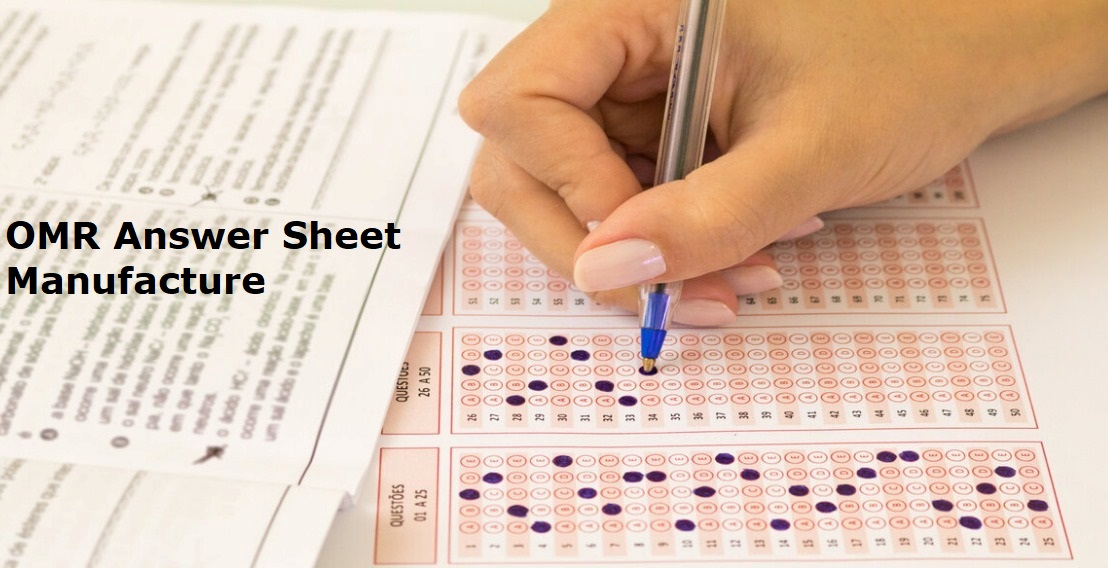

These sheets consist of a grid of bubbles or checkboxes that respondents fill in to indicate their answers.

If you're looking to manufacture OMR sheets, here are the general steps involved in the process:

Design the OMR Sheet: Determine the layout and structure of the OMR Sheet based on your specific requirements. This includes deciding on the number of questions, answer choices, and any additional information or fields you want to include, such as student ID or name.

Choose the Printing Method: Select the appropriate printing method for your OMR sheets. Common methods include offset printing and digital printing. Offset printing is generally suitable for large quantities, while digital printing allows for smaller print runs and customization options.

Determine the Sheet Size and Paper Type: Decide on the dimensions of the OMR sheet based on factors like the number of questions and the required spacing between answer options. Choose a suitable paper type, usually a thick paper or cardstock that prevents ink bleeding or smudging.

Printing the OMR Sheets: Once the design, printing method, sheet size, and paper type are finalized, you can proceed with printing the OMR sheets. It is essential to ensure accurate alignment and precise printing of the bubble or checkbox grids to ensure accurate scanning.

Quality Control: Implement strict quality control measures during the printing process to avoid any printing errors or inconsistencies. Thoroughly check a sample batch of printed sheets to ensure the bubbles or checkboxes are correctly aligned and clear for scanning.

Packaging and Distribution: After printing and quality control, package the OMR sheets appropriately to protect them during transportation and storage. Determine the required quantity for your specific needs and distribute them accordingly.

Keep in mind that OMR Technology also requires specialized scanning devices or machines to accurately read and interpret the marked responses on the sheets. These scanners use optical sensors to detect filled-in bubbles or checkboxes, which are then converted into digital data for further analysis.

If you prefer to outsource the Manufacturing of OMR Sheets, many printing companies specialize in producing such sheets. They can guide you through the design process, recommend suitable printing methods, and ensure the quality of the final product.

Remember to consult with a professional printing service provider to discuss your specific requirements and get precise guidance tailored to your needs.